The use of bone cement shaping molds

By injecting bone cement into the mold during surgery, the bone cement molding mold enables rapid solidification to form a bone cement spacer that is highly compatible with the joint anatomical structure, thereby establishing a mechanically stable support framework around the joint.By incorporating antibiotic components, the bone cement spacer can locally release high-concentration antibiotics, effectively eliminating bacteria and controlling infections.In addition to its space-maintaining function, the joint-specific bone cement spacer can also preserve the tension of ligaments and soft tissues around the joint, maintain a certain range of motion of the joint, facilitate exposure and reduction in secondary surgery, and achieve superior functional outcomes.

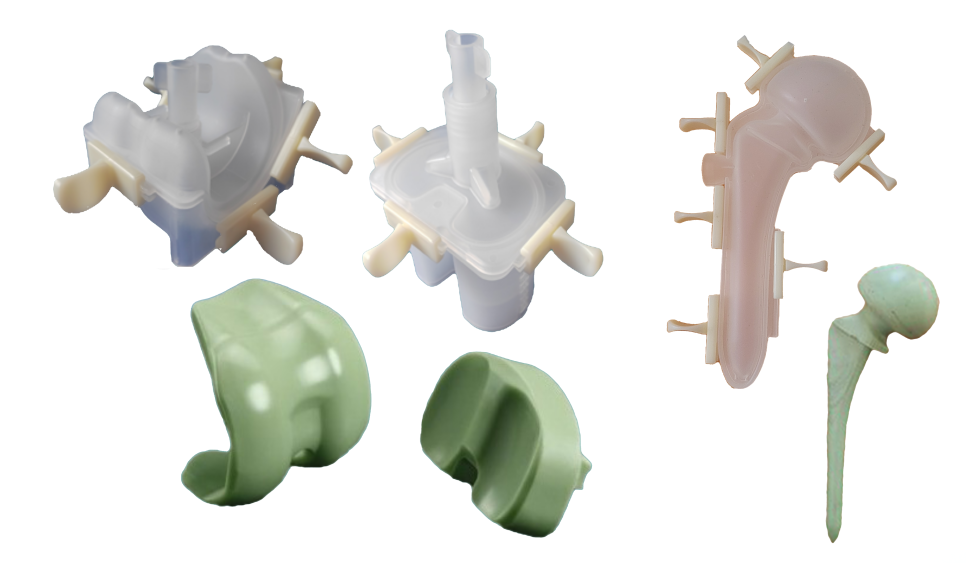

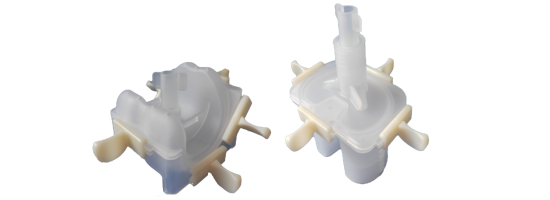

Knee Joint Bone Cement Molding Template

1、Product Introduction

The knee joint bone cement molding mold consists of a femoral mold component, a tibial mold component, and a gap measurement block. It is indicated for two-stage revision arthroplasty of the knee joint caused by infection, and is used to fabricate temporary femoral and tibial spacers via bone cement filling.

2、Product Features

1)Appropriate specifications of the bone cement molding mold can be selected according to the patient’s actual conditions and needs.

2)The gap measurement block enables more accurate measurement of the femoral-tibial gap, ensuring greater surgical precision.

3)The rotating thread design facilitates easier removal of the bone cement spacer.

4)The proportion of antibiotics is controllable, which effectively eliminates inflammation in the affected joint area and creates a favorable surgical environment for two-stage revision surgery.

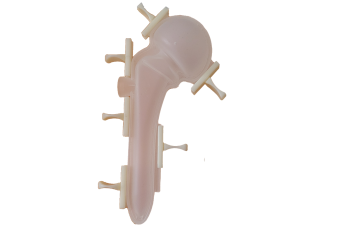

Hip Joint Bone Cement Molding Mold

1、Product Introduction

The hip joint bone cement molding mold is composed of Hip Mold A, Hip Mold B and a buckle, and is applicable for bone cement shaping in hip joint procedures.

2、Product Features

1)Appropriate specifications of the bone cement molding mold can be selected based on the patient’s actual conditions and requirements.

2)The design of the cement injection port allows for rapid filling of bone cement.

3)The material features excellent biocompatibility.

4)Ergonomically designed, the mold is lightweight, handy and easy to operate.

Company Introduction

Beijing Chunli Zhengda Medical Instrument Co., Ltd. (abbreviated as Chunli Medical) was founded in 1998. It is mainly engaged in the R&D, production and sales of medical devices such as orthopedic and dental products, biomedical materials and surgical robots. After nearly 30 years of development, Chunli Medical has become the only domestic A+H dual-listed enterprise in the orthopedic and dental fields.The company boasts national-level R&D platforms including a National Enterprise Technology Center and a National Postdoctoral Research Workstation. It has also been accredited as a National Champion Enterprise in Manufacturing (Single Product), a National High-Tech Enterprise, a National Specialized, Sophisticated, Unique and Novel "Little Giant" Enterprise, a National Intellectual Property Advantage Enterprise, and a Zhongguancun High-Tech Enterprise.Chunli Medical has led two National Key R&D Programs, and is the only domestic enterprise that has widely applied tantalum metal in joint, dental, spinal and sports medicine products. It has taken the lead in four "Challenge Program" projects launched by the Ministry of Industry and Information Technology (MIIT), promoting the industrialization of magnesium alloy, hydroxyapatite and tantalum metal as well as their clinical application in the domestic dental field. The company-led surgical robot "Challenge Program" project was awarded the title of "Excellent Unit", accelerating the R&D and clinical promotion of domestically-developed surgical robots.