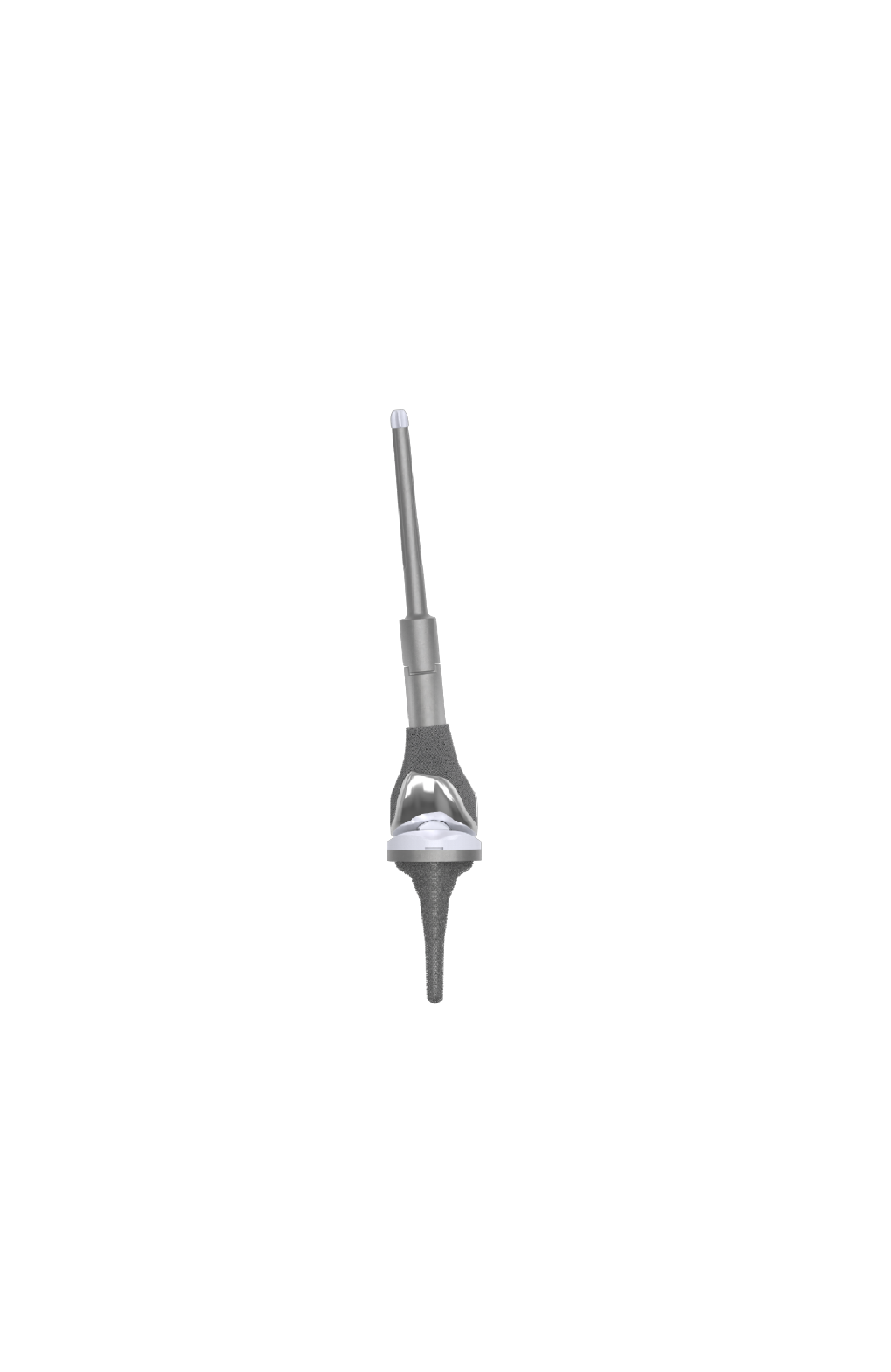

Modular knee prosthesis

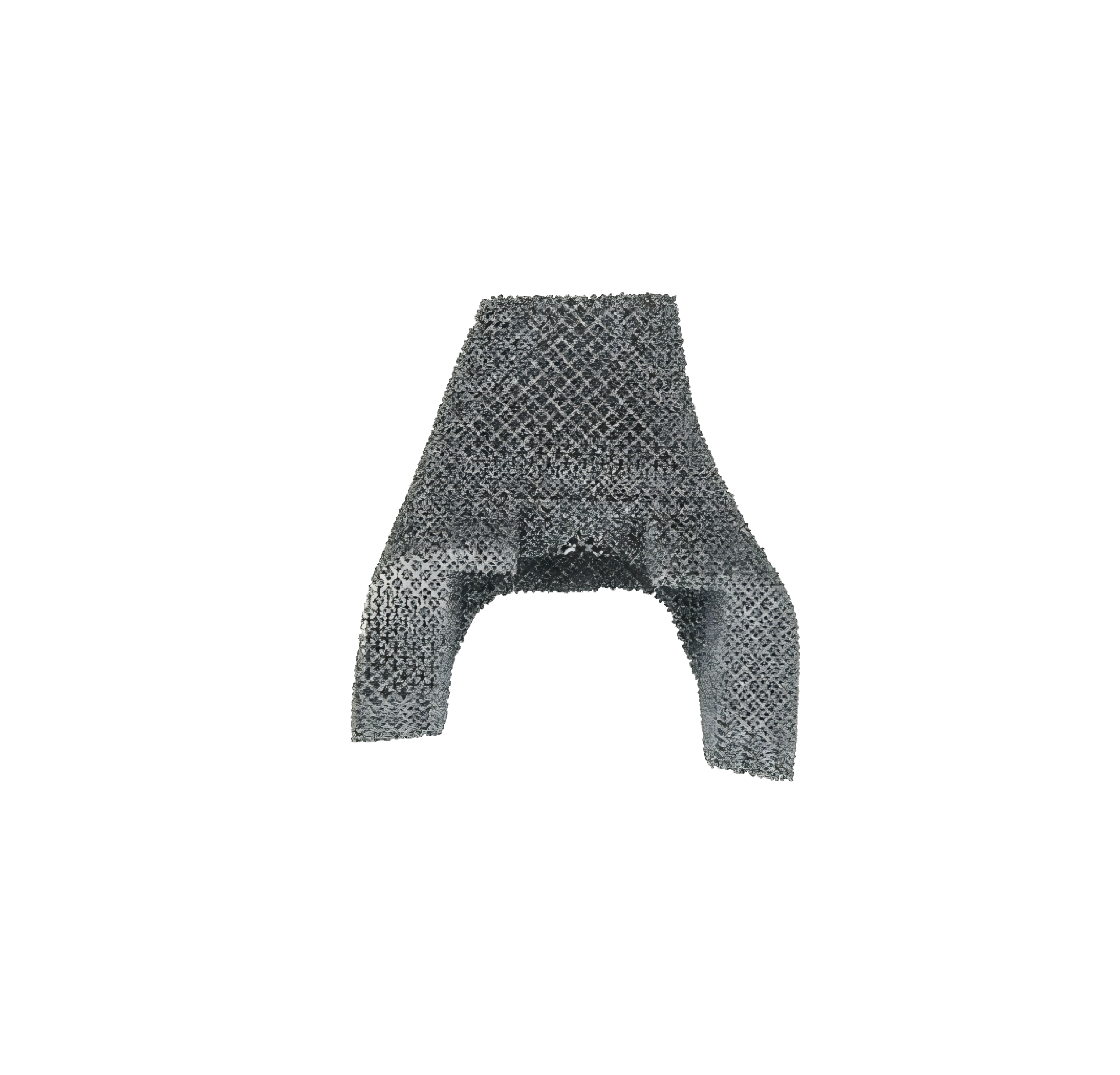

The knee joint prosthesis consists of Model GTDX and Model GTXX. The femoral condyles of the prosthesis are made of cast cobalt-chromium-molybdenum (CoCrMo) alloy. The tibial intramedullary nails, femoral intramedullary nails, osteotomy segments, adjustment pads Type 1, central shafts and tees are manufactured from forged titanium alloy (Ti6Al4V). The tibial tray and condylar outer sleeves are produced via rapid prototyping using titanium alloy powder (Ti6Al4V ELI). The tibial inserts, bushings, adjustment pads Type 2 and constraint components are made of molded ultra-high-molecular-weight polyethylene (UHMWPE). The osteotomy segments and femoral (tibial) intramedullary nails are fabricated from forged titanium alloy (Ti6Al4V) with their surfaces subjected to anodizing to form an oxide film.The 3D printing rapid prototyping process adopted is electron beam melting (EBM) additive manufacturing.

Social media